DLZ-15单螺杆榨油机性能简介

Brief Introduction of DLZ Single Screw Oil Press

一用途与特点

1st. Application and Characteristics

1. 用途

Application

本机适用于芝麻等高含油油料油脂的榨取。油料压榨前应进行预处理(蒸炒)。

The machine is suitable for extracting oil from materials with high oil content. Preprocessing of oil material should be made before its being processed.

2. 主要特点

The main Characteristics

本机工作原理新颖,结构合理,运转平稳,机械性能良好;主机传动系统的主要零部件如榨螺等均采用优质合金钢,并经严格的热处理,经久耐用,榨螺使用寿命≥10个月。

The rationale of the machine is an innovation compared with previous ones and it operates steady with reasonable structures and brilliant mechanical performances. The main transmission is composed of some important components, such as extracting screws of superior alloy steel with strict heat processing. The durability is perfect, for the estimated longevity is more than 10 months.

榨笼和主轴采用双阶压榨设计模式,具有大的压缩比和长径比,不仅使本机有良好的压榨工艺特性,而且有强有力的轴向推进作用,油料不易出现滑膛现象,同时独特多边形榨条结构具有最大的出油效率。

Screw cages and the main shaft adopts double order squeeze with large compression ratio and length-radius ratio. Either makes it the machine to run in a great pressing performance or it promises a great propelling force along the axial direction. Thus it is hard for oil material to slide within the machine barrel. In addition, the pressing strip with special polygon makes an outstanding contribution to the highest efficiency of pressing oil.

二.主要构造

2nd. Main Structure

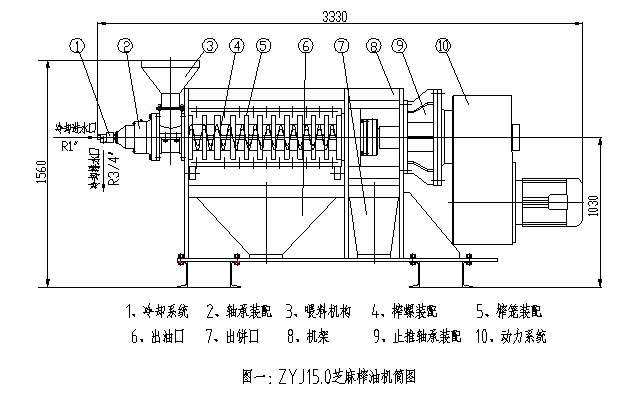

DLZ15.0型芝麻榨油机外形如图一所示。该机主要由动力系统、喂料机构、榨螺装配、榨笼装配、出油机构、出饼机构、机架、轴承装配、止推轴承装配和冷却系统等组成。

The Structure of DLZ15.0 for pressing oil from sesame is illustrated by the following graph below. It is composed of power system, feeding system, pressing screw system, pressing cage system, oil outlet system, oil cake outlet system, base support, bearing system, thrust bearing assembly as well as cooling system.

图一 DLZ-15榨油机示意图

三.工作原理与主要技术参数

3rd, Rationale and the main parameters

1. 工作原理

Rationale

启动电机,动力及运动经减速机直接传递至螺旋轴。打开喂料阀板,料斗内的油料通过重力进入螺旋轴的输送段,在榨螺、榨圈、条排和刮刀等构件的综合作用下,油料不断被挤压、剪切粉碎,在榨膛内经过连续压榨,油液不断流出,榨料中的残油愈来愈少,最后经出饼机构成瓦片状饼块排出机外。

Switching on motor, then power and motion will be transmitted directly to screw shaft. The oil material in the hopper will be move downward by the gravity to the inlet of screw transmission after the feeding panel has been opened. Hence oil material will be propelled forward by components, including pressing screws, pressing rings and scrapers. During the process, the oil material will continually be pressed while the oil is flowing out. Finally, less and less oil has been left behind in the cells and the chunk will be formed after it is coming out of the oil cake outlet.

2. 主要技术参数

The main parameters

主要技术参数见表1

The main parameters in table 1

表1 榨机性能参数一览表

Table 1 Performance Parameters of Oil Press

|

榨机型号 Oil Press Type |

DLZ-15.0 |

|

日生产处理量t/d Daily Yielding Capacity t/d |

5∽8 |

|

电机功率kw Motor Power kw |

11 |

|

螺旋轴转速r/min Screw Shaft Rotational Speed r/min |

13 |

|

整机外形尺寸 The Whole Size |

3390×660×1530 |

|

整机重量(Kg) The whole weight |

2200 |

|

芝麻压榨饼残 Residual Sesame Cake Percentage |

6-9%(平均饼残视品种 Average Percentage depends on material type)

|

表2 DLZ-15螺旋榨油机设备组成表

Table 2 DLZ Oil Press Facilities

|

序 号 Index |

系统设备说明 Illustration for Systematic Facilities |

数 量 Amount |

|

1 |

螺旋榨油机主机 The Main Facility of Oil Press 电机:专用 B5高效电机 4极,11Kw,IP55 F级 高效等级IE2; Motor: Specialized B5 High Efficiency Motor, 4 poles,11 Kw, IP55, F class, Efficiency Class IE2; 主轴承:SKF/NSK产品。主减速机博能 The Main Bearing: SKF/NSK Brand. BONENG Brand for The Main Reducer 螺旋和锥圈以及榨条采用耐磨材质 Screw and Cone Ring are made of wearproof material |

1套 1 Set |

|

2 |

技术资料 Technological Data 操作使用说明书、外形及安装尺寸图、基础图。 Manipulation Specification, Outline and Installation Drawing and Basic Drawings. |

|

四 图片示例

4th . Graphic Examples

|

|

样机实例

Prototype

|

|

芝麻饼残油: 6-9% (视不同品种)

Residue Sesame Oil Percentage:6-9%(Varies with types)